800.242.1150

Home » Industries » Truck Wash Water Recycle System at Maintenance Facilities

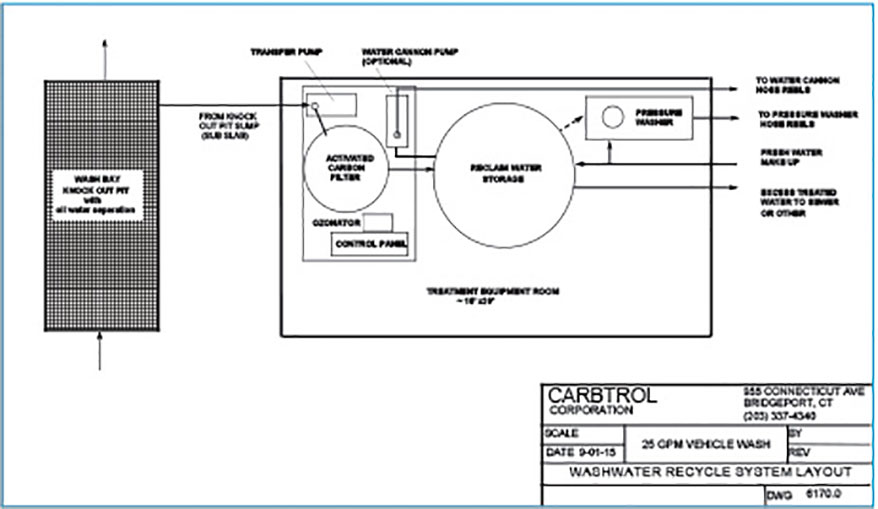

CARBTROL offers a complete line of truck wash water treatment and recycle systems using EPA-recommended activated carbon adsorption / oxidation technology to contain and treat waste waters generated from vehicle washing operations in Public Works Departments and Highway Garages. These systems are custom-designed for auto, truck, bus, train, construction and highway maintenance vehicles.

CARBTROL has utilized its

Features:

Benefits:

The CARBTROL system can provide 10-150 GPM of recycled wash water on a continuous basis. Many competitive treatment systems are limited to a flow capacity of 10 gallons per minute (GPM) and 1,000 to 2,000 gallons per day (GPD). The CARBTROL system has no difficulty in handling wash water from a heavy equipment washday. If a hose is left on or rainwater enters the washing area, the system handles these fluctuations easily.

The US EPA has published a listing of recommended treatment technologies for removing oil and grease, hydrocarbons and soluble organics from wastewater, which include activated carbon adsorption, chemical precipitation and oxidation. CARBTROL incorporates all of these technologies utilizing ultra high capacity granular activated carbons, which are designed to support locations requiring zero discharge of pollutants.

CARBTROL’s Truck Wash Water Recycle System handles changes in waste characteristics and flows, such as variations in temperature and pH, and temporary system shutdowns. Other treatment technologies may be subject to process upsets under these conditions, or may experience foaming problems from soaps, and detergents. These do not affect CARBTROL’s system.

Carbtrol’s Truck Wash Water Recycle System operates for extended periods without requiring any operator attention. The system is designed to allow easy inspection and repairs, if necessary. Typically, maintenance only requires one or two hours per week.

Read about CARBTROL’s Truck Wash Water Recycle Systems installed and planned at multiple locations along the NJ Turnpike:

At water high level, the pump engages and the water is vigorously agitated to ensure that loose waste, dirt, or grass are separated and do not accumulate in the sump.

Screened wash water is pumped from the transfer sump to the clarifier, where additional solids are removed by gravity separation. The clarifier additionally serves as a water storage tank, prior to final treatment and reuse.

Clarified wash water is pumped to the treatment skid, which includes activated carbon adsorption and oxidation as a final polishing step,producing a quality water ready for reuse.

Centrifugal Self Priming Process Transfer Pump – 2 HP with Inlet Strainers and Foot Valves

Primary Sump Level Controls

High-volume Activated Carbon Filter with Manual Backwash

Water Storage / Equalization Tank with Level Management

High volume Ozonation System with ½ HP Recirculation Pump

2 HP Recycle Water Booster Pump

Interconnecting Above Ground Piping and Valving

NEMA 4 Control Panel, including HOA Switches, Alarms, & Starters

Factory assembled- skid mounted- piping, filter and control components

Installation, start up and training of operating personnel

Technical support as required

Detailed Operating and Service Manufacturing

Systems are shop manufactured as modular components and shipped complete with all above ground equipment, ready for easy installation. Once installed, minimum maintenance is required. Activated carbon is simply replaced annually.