800.242.1150

Home » Industries » Tank Vent VOC Emission Control for Chemical/Industrial Plants

Carbtrol Corporation has supplied tank vent VOC emission control systems utilizing activated carbon filtration to chemical/industrial facilities throughout North America. VOC emissions and odors from a variety of industrial applications must be treated to conform to local and EPA regulations.

Carbtrol Corporation can design a VOC emission control or odor removal system to meet your requirements. Typical applications include tank vents, process vents, VOC emissions, acid gas removal, ammonia removal, formaldehyde removal, mercury removal, fugitive emissions, and odor control. With systems ranging from our drum canister filters to our large high flow adsorbers as well as adsorber with fan systems, our engineers can provide the right solution for you.

Activated carbon plays a crucial role in mitigating Volatile Organic Compound (VOC) emissions from tank vents, offering an effective and widely adopted solution in the industrial sector. Activated carbon, characterized by its high surface area and porous structure, provides an excellent medium for adsorption, the process by which VOC molecules adhere to the carbon surface. When applied to tank vent emissions, activated carbon acts as a filter, capturing and retaining VOCs before they are released into the atmosphere. This technology is particularly effective in removing a broad spectrum of VOCs, ranging from hydrocarbons to various chemical compounds, making it a versatile and reliable solution for emission control.

The process of using activated carbon for VOC tank vent emissions typically involves the installation of adsorption units within the venting system. These units contain beds of activated carbon through which the vented gases pass. As the gases flow through the activated carbon, VOC molecules adhere to the carbon surface, effectively removing them from the gas stream. Periodically, the saturated activated carbon is either replaced or regenerated, depending on the specific system design.

The widespread adoption of activated carbon technology for VOC tank vent emissions aligns with regulatory efforts to minimize environmental impact. Industries across various sectors, including petrochemical, manufacturing, and storage facilities, recognize the importance of controlling VOC emissions for environmental sustainability and compliance with air quality standards. Activated carbon, with its proven effectiveness and adaptability, continues to be a key player in advancing emission control strategies and promoting responsible industrial practices.

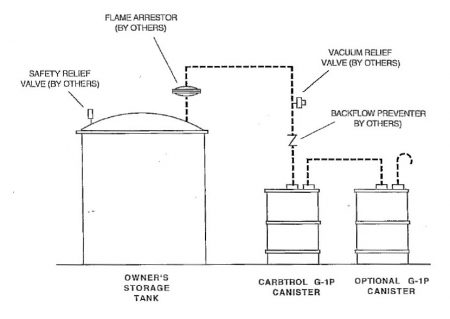

Carbtrol provides several different drum-size activated carbon canisters to control organic process gases exiting storage tanks during filling operations and from temperature changes. These are very effective in removing toxic materials and odors from discharge to atmosphere.

Contact us today to discuss your tank vent VOC emission control system with our expert engineers!