800.242.1150

CARBTROL offers a complete line of proven, high quality vehicle / equipment wash water recycling systems for commercial, industrial, and military operations. Our wash water recycle systems are ideal for public works garages and highway equipment wash operations. Vehicle / equipment wash water is reclaimed, treated and recycled, which conserves water and reduces or eliminates contaminant discharge. Modular treatment packages are available for water flows ranging from 10 to 240 GPM, with custom equipment wash water systems designed by experienced engineers for flows up to 1000 GPM.

Employing state-of-the-art activated carbon adsorption, chemical precipitation, and oxidation as recommended by the US-EPA, CARBTROL’S systems are designed to remove contaminants – including suspended solids, petroleum bi-products, herbicides, pesticides, gasoline, and other organic materials – and ensure maximum water clarity for immediate and continuous vehicle wash re-use.

CARBTROL’S Equipment Wash Water Recycle Systems are designed so that they can be combined with a variety of existing or planned commercial and industrial washing operations. Systems can be customized to your specifications by highly experienced engineers

The cost-efficient equipment wash water recovery system is well engineered to operate smoothly with very little maintenance. Simply replace the activated carbon annually. Full water flow is available at all times, with minimum need for operator attention. With CARBTROL equipment wash water recycle systems, there’s no extra start up time, no monthly biologic additives, and no costly and time-consuming service requirements.

CARBTROL’S Wash Water Recycle Systems are designed to handle changes in waste characteristics and flows, such as small spills or leaks of chemicals or fuel, variations in temperature and pH, or temporary system shutdowns. Other treatment technologies may be subject to process upsets under these conditions. Other wash water recovery systems may also experience foaming problems due to soaps, detergents, or soil conditioners. CARBTROL’S systems are not affected by these fluctuations.

CARBTROL has an ever-expanding base of installed systems in a wide range of wash water recycle applications:

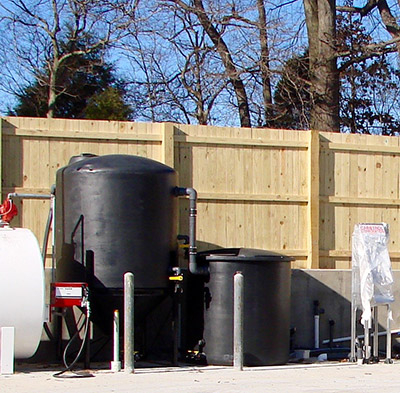

System designed for highway maintenance operations

Compact golf course wash water recycle system for minimum space, Maximum Efficiency

Large scale system custom-designed for oversized military equipment

Large industrial-use systems custom-designed for a wide variety of industries

CARBTROL wash water recycling systems are manufactured in our factory in Stratford, CT and shipped to our clients location, with CARBTROL technical experts available to supervise installation and train operators as required.

At water high level, the pump engages and the water is vigorously agitated to ensure that loose waste, dirt, or grass are separated and do not accumulate in the sump.

Dirty water is pumped from primary sump to the solids separation screen. Filtered water passes through the screen and flows into a transfer sump. If applicable, waste, grass, and dirt are collected in a trash cart.

Screened wash water is pumped from the transfer sump to the clarifier, where additional solids are removed by gravity separation. The clarifier additionally serves as a water storage tank, prior to final treatment and reuse.

Clarified wash water is pumped to the treatment skid, which includes activated carbon adsorption and oxidation as a final polishing step,producing a quality water ready for reuse.

Systems are shop manufactured as modular components and shipped complete with all above ground equipment, ready for easy installation. Once installed, minimum maintenance is required. Activated carbon is simply replaced annually.

Read the case study featuring our Wash Water Recycling System on New York Golf Course Foundation’s Best Management Practices.

Discusses carbon adsorption, adsorption isotherms, and design considerations for liquid phase activated carbon systems